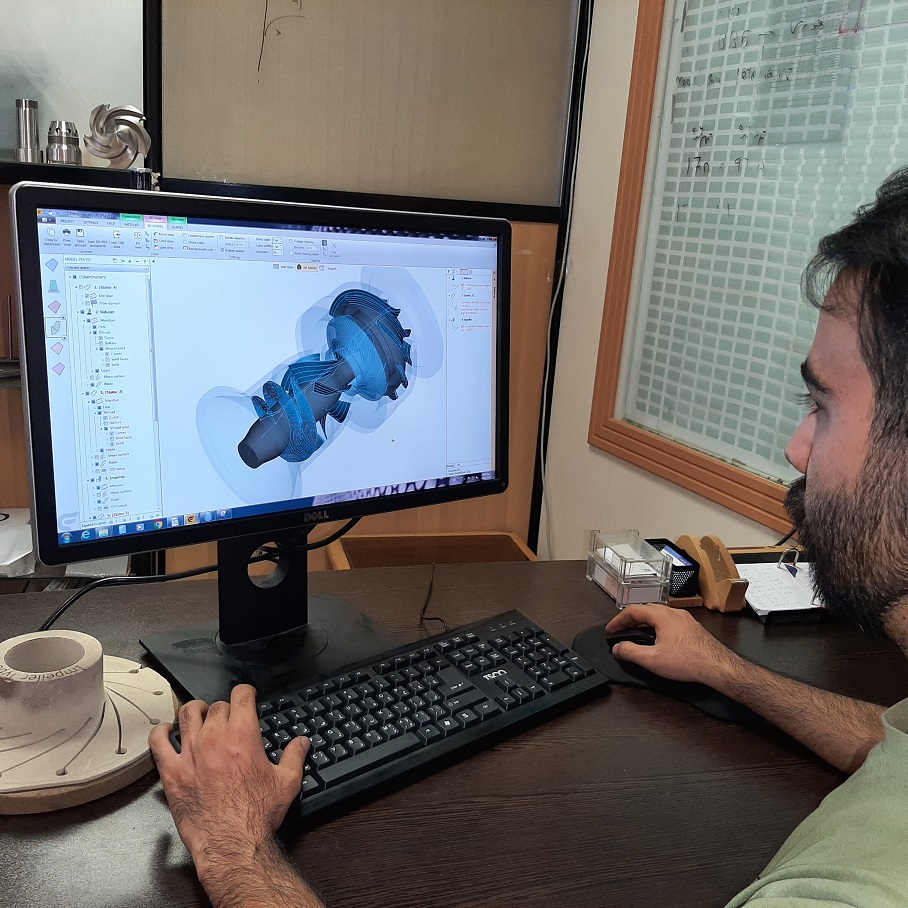

Design and engineering

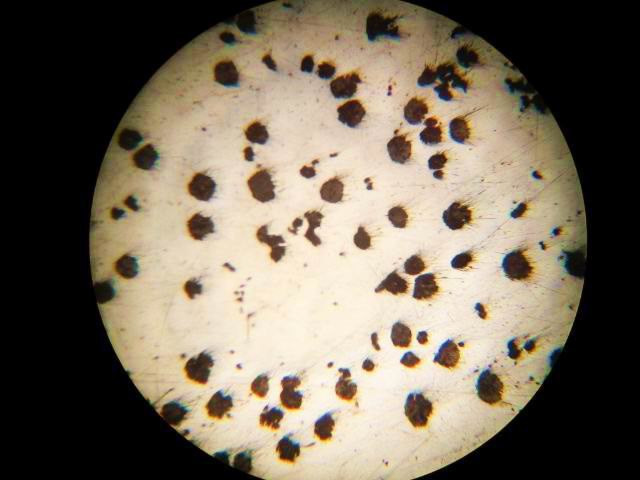

In this unit, our team begins the process by accurately measuring the part using precision tools such as calipers, micrometers, internal gauges, and optical devices. After registering the dimensions, we use advanced analysis and design software such as Catia, SolidWorks, CFturbo and Ansys to perform reverse engineering and design processes. This ensures that our products are of the highest quality and meet all the necessary specifications.